Creating a silicone molds for resin projects is an exciting and creative endeavor. Whether you’re a hobbyist or a professional, mastering the art of silicone mold making will elevate your craft.

This guide will take you through the essential steps, from selecting the right materials to caring for your molds, ensuring you get the best results every time.

What Materials Do I Need To Make A Resin Mold?

The first step for creating silicone molds for resin is selecting the appropriate materials. Not all silicone and resin are created equal, and choosing the right type is crucial for your project’s success.

Look for silicone that is specifically designed for mold making, which typically offers the right balance of flexibility, durability, and detail capture. The resin you choose should match your project’s requirements in terms of curing time, clarity, and hardness.

For silicone, RTV (Room Temperature Vulcanizing) silicone is popular due to its ease of use and excellent detail capture. When it comes to resin, epoxy resin is a common choice for its clarity and strength, but be sure to select a formula that suits your project’s specific needs.

No products found.

How To Prepare the Mold

Preparing the mold is a critical step in the process. Begin by mixing your silicone according to the manufacturer’s instructions.

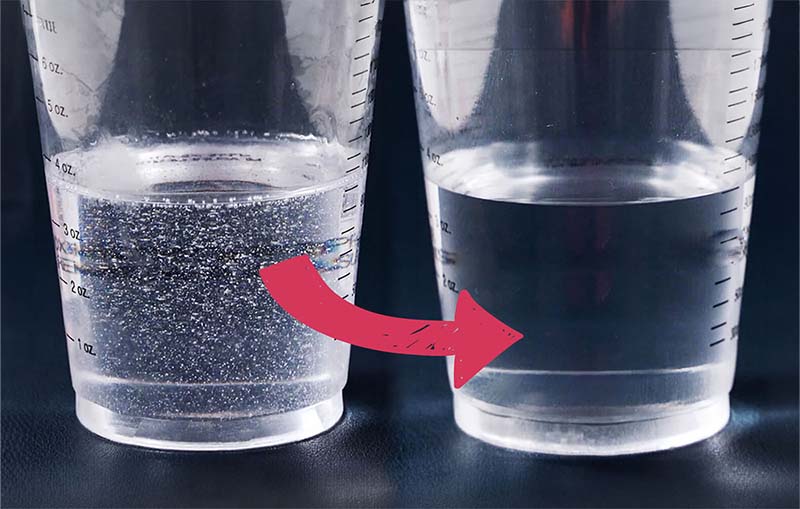

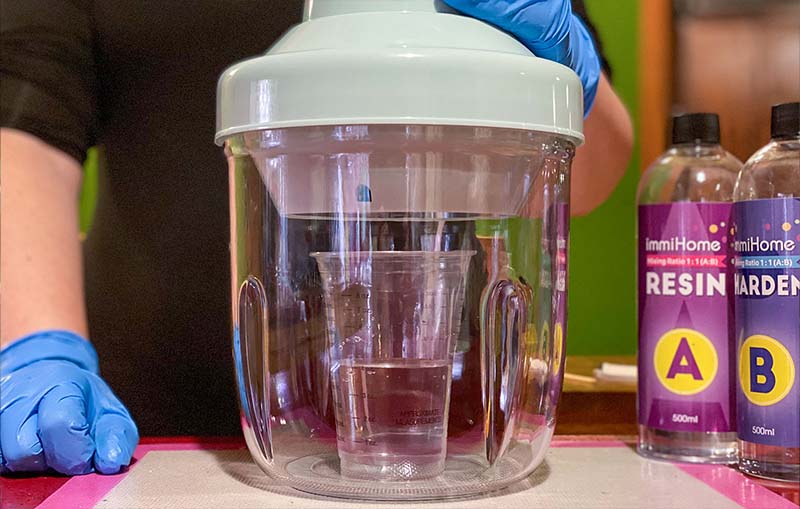

It’s essential to achieve the right ratio of hardener to silicone to ensure proper curing. Once mixed, degassing the silicone is a crucial step to remove any trapped air bubbles.

This can be done using a vacuum chamber or by carefully tapping and stirring the mixture.

Next, pour the silicone into your mold box or frame, which should contain the object you’re making a mold of. Pour slowly and in a thin stream to minimise air bubbles and ensure the silicone envelops the object completely.

No products found.

Discover the ultimate step-by-step guide to silicone mould making. Unlock endless possibilities with our comprehensive tutorial. Get started today!

Best Techniques for Casting Resin in A Silicone Mold

Casting resin in your silicone mold requires careful preparation and technique to achieve clear and bubble-free results.

Begin by preparing the resin mix, following the manufacturer’s instructions closely to get the correct ratio of resin and hardener. Pouring the resin slowly and in a controlled manner can help minimise air bubbles. Additionally, using a vacuum chamber for resin can help pop any bubbles that do surface.

Ensuring your resin is at the right temperature and pouring in layers can also help reduce bubbles and ensure a clear finish. Patience is key during this step to avoid rushing and potentially introducing more air into the mix.

No products found.

Ensuring Fine Detail Capture

Capturing fine details in your silicone mold is crucial for high-quality resin casts. To ensure your mold captures every detail, once again consider using a vacuum chamber for the degassing process to remove all air bubbles. Additionally, applying a silicone release spray to the object before encasing it in silicone can help capture finer details and make de-molding easier.

Taking the time to properly position your object and eliminate any undercuts or areas where air could be trapped will also improve detail capture.

No products found.

Common Problems and Solutions in Silicone Mold Making

Even experienced mold makers can encounter issues. Common problems when making silicone molds for resin include air bubbles, incomplete curing, and issues with de-molding. Try the following to avoid these issues:

- Air Bubbles: Use degassing techniques and pour your silicone carefully to minimize bubbles. If bubbles form, try using a vacuum chamber or a pressure pot.

- Incomplete Curing: Ensure you’re mixing the right ratio of silicone and hardener and allowing enough time for the mold to cure completely.

- Mold Release Issues: Applying a silicone release agent can prevent the resin from sticking to the mold, making de-molding smoother and protecting your mold

Caring for and Storing Your Silicone Molds

Proper care and storage of your silicone molds are vital for their longevity. Clean your molds after each use with soap and water, and avoid using abrasive materials that can damage the surface. Store molds in a cool, dry place away from direct sunlight to prevent warping or degradation.

By treating your molds with care, you will help them remain in top condition for many casting sessions to come.

Making Silicone Molds For Resin – FAQs

What safety measures are needed when using silicone and resin?

When working with silicone and resin, it’s essential to work in a well-ventilated area, wear protective gloves and eyewear, and follow the manufacturer’s safety guidelines to minimize exposure to potentially harmful chemicals.

How often can you reuse silicone molds?

The reusability of silicone molds varies depending on the material’s quality, the complexity of the mold, and the casting material used. Generally, silicone molds can be used multiple times, but they will eventually wear out or lose detail after extensive use.

Are there eco-friendly alternatives to silicone and resin?

There are eco-friendly alternatives to traditional silicone and resin, such as biodegradable resins and organic silicones. These materials aim to reduce environmental impact, though they may differ in performance and cost compared to conventional materials.