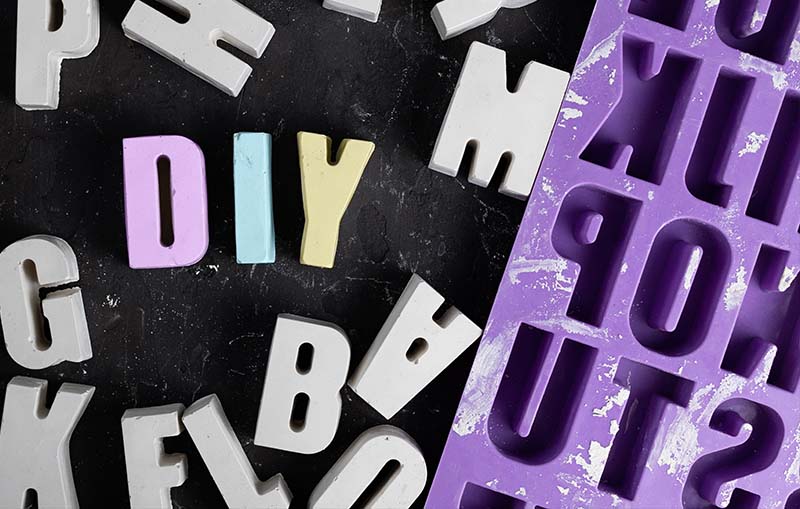

DIY and professional crafting allow for endless creativity by combining different materials and methods. One innovative approach is using silicone molds with concrete. This article explores the feasibility and techniques of using silicone molds for concrete projects. It provides insights and guidance for hobbyists and professionals working with these materials.

Can You Use Silicone Molds for Concrete?

The short answer is yes, you can use silicone molds for concrete. Silicone molds are favored for their flexibility, non-stick properties, and durability, making them an excellent choice for concrete casting.

They can withstand the rigidity of concrete without losing their shape, allowing for the creation of intricate and detailed objects. Whether you’re making decorative items, architectural elements, or functional pieces, silicone molds can help you achieve precise results with concrete.

What Concrete Is Best for Silicone Molds?

Not all concrete mixes are created equal, especially when it comes to casting in silicone molds. The ideal concrete for silicone molds should have a fine texture and a low water-to-cement ratio.

A high-quality concrete mix designed for casting or a specially formulated mix like countertop or architectural grade can yield the best results.

These mixes are designed to flow into the mold easily, capturing details while minimizing air bubbles and defects.

No products found.

Silicone moulds are versatile tools commonly associated with baking and resin crafts. However, what about using silicone moulds with cement?

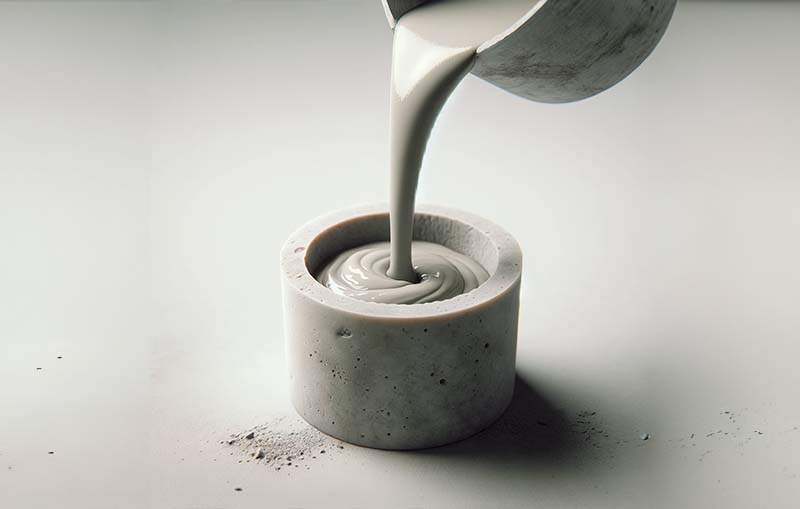

How Do You Fill a Mold with Concrete?

Filling silicone molds with concrete requires precision and care. Here’s a step-by-step guide to ensure a successful cast:

- Prepare Your Work Area: Ensure your work surface is level and protected. You can use a plastic sheet or tarp to safeguard the area from spills.

- Mix the Concrete: Follow the manufacturer’s instructions to mix the concrete. Aim for a consistency that’s pourable yet not too runny, similar to thick pancake batter.

- Pour the Concrete: Gently pour the concrete into the mold, starting from one corner and gradually covering the entire area. Tap the sides of the mold to release any trapped air bubbles.

- Level the Surface: Use a spatula or a similar tool to smooth and level the top surface of the concrete.

- Curing: Allow the concrete to set and cure as per the instructions on the concrete mix. The environment’s temperature and humidity can affect curing times, so adjust accordingly.

No products found.

Which Silicone Molds Are Best for Concrete?

When selecting silicone molds for concrete, consider the following factors:

- Thickness: Thicker molds are more durable and can withstand the weight of concrete better.

- Design Complexity: Choose a mold that can capture the level of detail you desire in your final piece.

- Size and Shape: Ensure the mold’s size and shape are suitable for your project’s requirements.

- Release Properties: Choose molds where objects can be removed easily.

Quality molds from reputable suppliers often provide the best results, ensuring the longevity of the mold and the quality of the concrete object.

No products found.

How Long Do You Leave Concrete in the Mold?

The time required to leave concrete in the mold can vary based on the type of concrete used, the size of the object, and environmental conditions. Ideally leave small to medium-sized objects in the mold for at least 24 hours. Larger or more complex pieces may require longer, sometimes up to 48 hours or more. This will ensure they are fully cured and strong enough to be demolded without damage.

It’s crucial to refer to the concrete mix’s specific curing time instructions and consider factors like temperature and humidity, which can accelerate or slow down the curing process. Once de-molded, the concrete should continue to cure and gain strength over the next few weeks.

Using silicone molds with concrete opens up a world of possibilities for creating detailed, precise, and durable objects.

Whether for artistic endeavors, home decor, or functional items, the combination of silicone’s flexibility and concrete’s strength offers a versatile medium for crafters and professionals.

By choosing the right concrete mix, carefully filling and curing the mold, and selecting high-quality silicone molds, you can achieve impressive results that highlight the best of both materials.

Using Silicone Molds with Concrete – FAQs

Can silicone molds for concrete be reused for food?

Generally, it’s not recommended to use silicone molds for food if they’ve been used with concrete. Concrete can leave residues that might not be safe for food contact.

Do temperature or humidity affect concrete curing in silicone molds?

Yes, temperature and humidity can influence the curing process of concrete. High humidity and low temperatures can slow down curing, while high temperatures can speed it up but might lead to weaker structures.

Can you fix blemishes on de-molded concrete objects?

Small imperfections can be sanded down. For larger defects, filling them with a concrete patch or a similar material and then sanding for a smooth finish might be necessary.